Electrolytic purification of copper: Blister copper (containing 99% copper) is pre-made into thick plates as the anode, pure copper is made into thin sheets as the cathode, and a mixture of sulfuric acid (H2SO4) and copper sulfate (CuSO4) is used as the electrolyte. After electricity is applied, copper dissolves from the anode into copper ions (Cu) and moves to the cathode. After reaching the cathode, electrons are obtained and pure copper (also called electrolytic copper) is precipitated at the cathode. Impurities in blister copper, such as iron and zinc, which are more active than copper, will dissolve into ions (Zn and Fe) together with the copper.

Since these ions are less likely to precipitate than copper ions, the potential difference can be appropriately adjusted during electrolysis to prevent these ions from precipitating on the anode. Impurities that are less reactive than copper, such as gold and silver, are deposited at the bottom of the electrolytic cell. The copper plates produced in this way are called "electrolytic copper". They are of extremely high quality and can be used to make electrical products. What is deposited at the bottom of the electrolytic tank is called "anode mud", which is rich in gold and silver and is very valuable. Taking it out and processing it has extremely high economic value. Electrolytic copper can be further processed into extremely fine electrolytic copper powder.

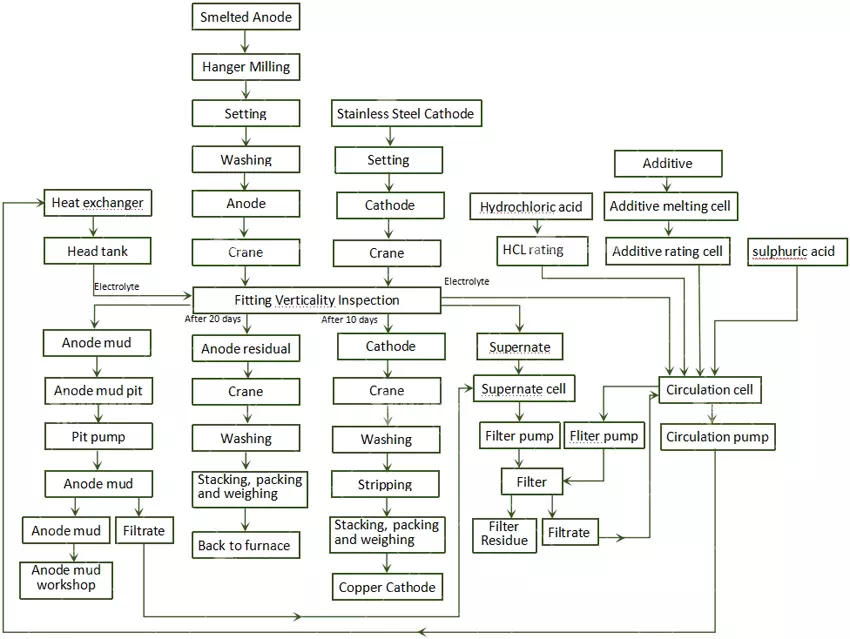

The principle of copper electrolytic refining is as follows:

Copper Electrolysis Workflow

Anodic reaction: Cu—2e = Cu2+Me—2e = Me2+H2O—2e=2H++1/2O2SO42-—2e=SO3+1/2O2 where Me represents Fe, Ni, Pb, As, Sb and equal proportions of Cu The more electronegative metals, they dissolve from the anode into the solution. The reaction of H2O and SO4 2- losing electrons will not occur under normal circumstances because its potential is more positive than copper. The potential of the precious metal is corrected and does not dissolve into the anode mud.

Cathode reaction: Cu2++2e=Cu2H++2e=H2Me2++2e=Me. In these reactions, metal ions with a standard potential that is more positive than copper and with a higher concentration may be reduced on the cathode, but they are not dissolved at the anode. , so only copper ion reduction is the main reaction in the cathode reaction.

Copper electrolysis related equipment:

1. Special lifting equipment for copper electrolysis

Copper electrolysis automatic crane and spreader; automatic crane 2mm high-precision positioning; special crane;

2. Robot cathode stripping unit

Arrangement and spacing device; transfer trolley device; washing system; rapid air drying; cathode stripping device; cathode plate verticality detection device; cathode copper plate conveying, stacking, and packaging device;

3. Residual electrode washing unit

Automatic cleaning system; stacking device; fully enclosed flip structure;

4.Anode shaping unit

Copper anode; anode plate conveying mechanism; shaping machine; straightening headset; milling headset; anode plate discharging machine; high-speed milling technology; transverse transfer vehicle;

5. Permanent stainless steel cathode plate

316L stainless steel plate; conductive rod; insulating edge strip;

(In practice, the equipment required is determined on a case-by-case basis.)

Uses of electrolytic copper:

Copper is the most widely used and consumed in the electrical and electronic industries, accounting for more than half of total consumption. Used for various cables and wires, windings of motors and transformers, switches and printed circuit boards, etc.

In machinery and transport vehicle manufacturing, it is used to manufacture industrial valves and fittings, instruments, plain bearings, moulds, heat exchangers and pumps, etc.

It is widely used in the chemical industry to manufacture vacuum vessels, distillation pots, brewing pots, etc.

In the construction industry, it is used as various pipes, pipe fittings, decorative devices, etc.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231