500-5000 Kg/Day

Scrap Copper, Crude Copper, Impure Copper, Copper Powder from PCB Recycling, etc.

99.99% Copper

SEND EMAIL: sunymachine@gmail.com

Copper Electrolysis Machine is used to Refine the copper from the mixed metal powder, copper purity 99.99%.

Anode plates are hung by their "handles" in electrolytic copper refining tank. Pure copper cathode sheets suspended on solid copper bars are inserted into the same tank, one sheet between each anode. When an electric current is passed from the anodes through the electrolyte to the cathodes, copper from the anodes moves into the solution and is plated onto the starter sheet. Impurities from the anodes settle to the bottom of the tank.

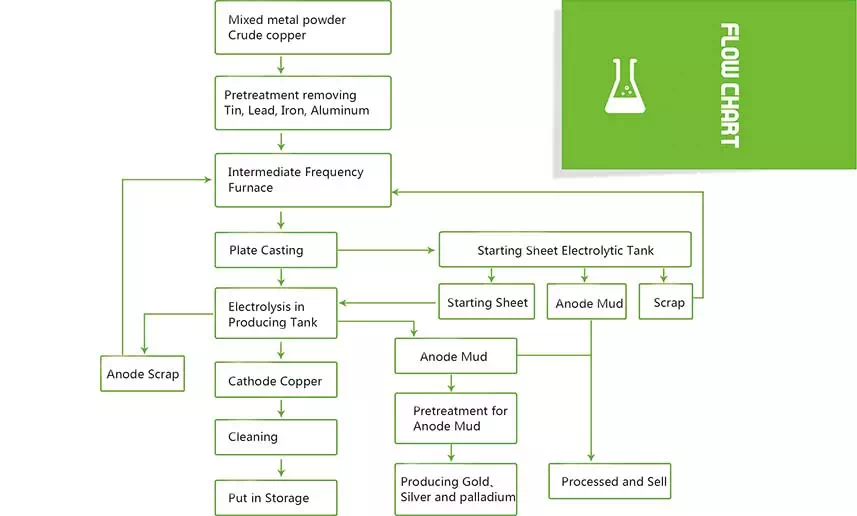

The copper anode will be casting into anode plates in molds semi-automatically. After pretreatment removing of tin, lead, iron,aluminum starts charging of the copper material into the furnace which is followed by smelting process. When the impurities are removed follows the slag removal and phase of reduction with natural gas. Reduction is aimed to remove the free oxygen. After the reduction the process is ended by casting, where the final product is casted into the form of copper anodes.

The refining anodes taken out from the refining furnace is changed into electrolytic copper with purity of 99.99% through an electrolysis process: During electrolysis, copper (II) ions leave the impure copper anode and since they are positive, migrating to the negative cathode. From time to time, the pure copper is scraped off the cathode. Impurities from the copper anode, such as gold, silver, platinum and tin, collect at the bottom of the electrolyte solution, deposited as anode slime.

Scrap Copper, Crude Copper, Impure Copper, Copper Powder from PCB Recycling, etc.

The Separated metal part be smelted and cast into anode board for the process of copper electrolysis. since a large number of non-ferrous metals, rare earth metals and precious metals are used in the production of the circuit board , if in conventional electrolytic method, the anode often get passivated and causing electrolysis can not work normally. Here we suggest adopting pulse automatic pole changing electrolysis system, it not only solve the anode passivation problem effectively, but also help anode mud loose off. The time is set and adjusted arbitrarily by the control cabinet.

The electrolysis system is composed of a number of automatic IGBT power control module, belonging to digital pulse power equipment. Semiautomatic formwork mold is adopted during casting of the anode plate, and in order to shorten the electrolysis cycle, the anode thickness is generally controlled to 10 mm to 30 mm. In the electrolysis, Cu2+ obtains the the electron and turns into pure copper at the cathode.

At the same time, gold, silver, palladium and the platinum remains in the anode mud. the anode mud be washed, undertake reducing smelting and oxidation smelting in frequency furnace, then we can get the precious metal alloy block. Then have it water broken, and then through the precious metal to make liquid extraction separation and refining a variety of precious metals.

In the workshop, all place producing exhausting gas must be set up tail gas absorption device with the ozone, all places producing tail liquid must establish fluid diversion device, the tail liquid will be lead to the waste water treatment plant and be discharged or reused after meet the standard.

1. After processing the tail liquid can be consistent with national environmental requirements;

2. Automatic controlling, compared with other processes, labor costs can be reduced by 50%;

3. The exhaust gas treatment system can produce useful chemicals, creating added value;

4. Advanced technology make the electrolytic cycle much shorter.

| Model | Capacity(Kg/Day) | Energy Consumption(KWH) | Electrolytic Cycle | Copper Capacity(Kg) | Copper purity |

| TDJ-500 | 500 | 280 | 15 Days/48H | 370 | 99.99% |

| TDJ-1000 | 1000 | 570 | 15 Days/48H | 750 | 99.99% |

| TDJ-2000 | 2000 | 1130 | 15 Days/48H | 1500 | 99.99% |

| TDJ-5000 | 5000 | 2850 | 15 Days/48H | 3750 | 99.99% |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.