Depends on number of operators

Waste TV, Waste Computer, Waste Monitor Sets

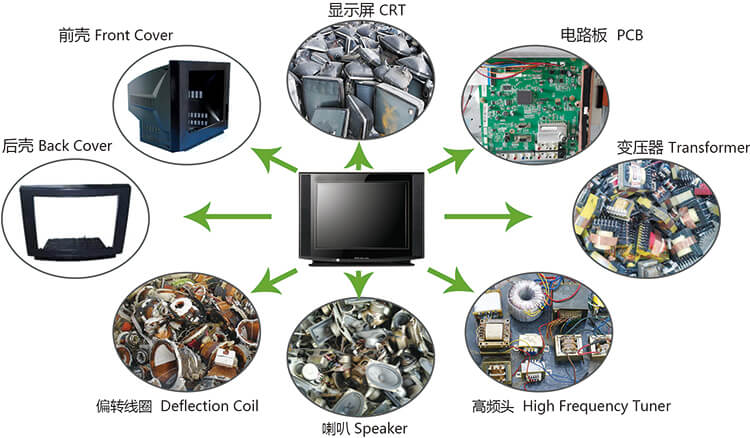

Metal parts, Plastic parts, CRT and PCB

SEND EMAIL: sunymachine@gmail.com

Here the waste TV, computer and monitor sets are primarily disassembled into major parts, among which metal parts, plastic parts, CRT and PCB are dismantled directly by intelligent conveying and manual work with our new advanced technology. This is very important in the process of e-waste recycling.

TV/Computer Monitor Disassembly Line consists of 9 roller conveyors, 26 cross-ball work table, a lighting set, a pallets loop-back device and 26 pallets.

At the beginning of the line, the roller conveyor carries TV/Monitor sets to cross ball work tables. Then operators will remove the back cover which is mainly made by plastic and reusable. After that, do the deflection coil disassembly which has copper around it. And then recycle different kinds of metals after disassembled PCB. Above removed parts are collected and classified respectively. Those who need further processing will be sent to next recycling station. And the empty pallets are automatically sent back to the beginning for next-time using through pallets loop-back device.

1. Dismantles waste TVs and monitors for recycling with advanced disassembly technology;

2. Optimal combination of intelligent conveying and manual disassembly;

3. Low power consumption and high efficiency, up to 100pcs per hour;

4. Low malfunction rate, low maintenance cost, and extremely long service life;

5. Can be used with CRT separator and glass washing machine;

6. Comply with environmental requirements in most countries of use;

7. NO waste gas, no waste water, no dust pollution.

Compliant with Emission Standard of Air pollutants: GB16297-1996

Compliant with Noise Control Design of Industrial Enterprises: GB12348—2008

| Option | Specification |

| Size | 26400×3240×2100 (mm) Or per request |

| Stations | Number of stations per request |

| Capacity | Depends on number of operators |

| Air Pressure | 0.6-0.8Mpa |

| Power | 380v/22.5kw or 220v/0.48kw adapt to voltage of all countries |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.