100-1000 Kg/H

Automobile Copper Wire, Car Bottom Wires, Motorcycle Cable Wire, Computer Cable Wire, Communication Cable, etc.

Copper Granules, Plastic Granules

SEND EMAIL: sunymachine@gmail.com

Cable Wire Recycling Machine is dry type structure, main used to all kinds of waste copper line will be separated into tiny copper particles and PVC particles,copper cable wire granulator is an indispensable environmentally friendly machine in recycling waste cables, waste copper wires whose diameter should be below 20mm, such as auto electric wire, motorcycle electric wire, and computer wires etc.

Cable Wire Recycling Machine is suitable for the wire diameter in 0.3 mm Φ 20 mm, such as automobile wire or car bottom wire, motorcycle wire, computer wire and communication cable, etc

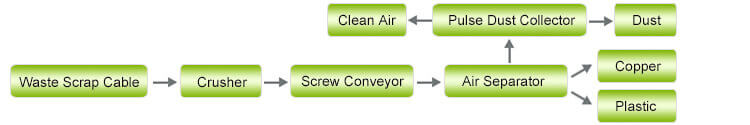

1 .Copper wire crushing process:

Put waste copper wire/cable into crusher to grind the wire into granular mixture. The crusher blade of high quality would change the wires or cable into particles.

2 .Copper clad collecting:

After crushing the mixture of copper and plastic will be blow to the separating process by a high pressure blower. The crushed granule particle are driven by two vibrating motor. Because of different gravity, the copper clad is easily floating up and collected by the blower.

3 .Separating and copper granule collecting process:

The vibrating screen is en installed which makes the separating process much easier. Also during vibrating process, a blower wiH pull the plastics out from one of the discharging hole. Then the copper granule will be filtered by vibrating screen of 150 mesh.

1. Equipped with PLC control system, reliable operation, low noise and large handling capacity;

2. Double crushing process improves the copper recycling purity, recycling 99% copper from scrap copper wires or cables;

3. Independent conveyor to delivery mixture of copper and plastic, making the whole working plant more stable;

4. The blade of the crusher can be removed to be sharpen;

5.When processing the waste copper wires, it produces no dust, no environmental pollution.

| Model | Capacity(Kg/H) | Dimensions(mm) | Total Power(Kw) |

| CR-200 | 100-200 | 1800*1800*2500 | 20 |

| CR-300 | 200-300 | 4500*2500*4000 | 55 |

| CR-500 | 400-500 | 12000*5000*4500 | 105 |

| CR-1000 | 800-1000 | 20000*10000*4500 | 195 |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.