100--300 Kg/Day

Chip, North and South Bridge, Storage Chip, Integrated Circuits, etc.

Gold, Silver, Palladium, Platinum

SEND EMAIL: sunymachine@gmail.com

Precious Metal Refining Machine is used to refine the precious metal(such as gold,sliver,platinum,palladium) from all kinds of e-waste.

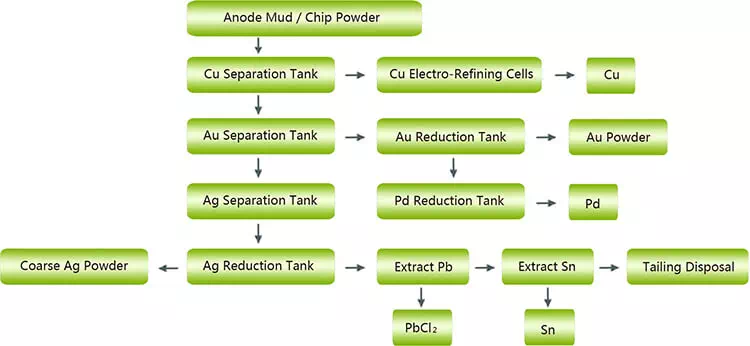

After dismantling the elements can not be returned, such as chip, north and south bridge, storage chip, integrated circuits, field-effect plastic components are the highest collective material containing gold and silver meets element unified treatment, can use ozone roasting (ozone can completely destroy the formation of harmful combustion smoke), roasting residue using soluble carrier, leaching of copper, tin, gold platinum palladium hydrochloric acid leaching medium, extraction of gold, platinum and palladium.

The chip capacitors highly contain silver-palladium-containing separate with high acid method independent refining silver palladium, for the gold-plated silver circuit board, plug ammonium polysulfide recommend using non-toxic methods to extract gold and silver plated quick retreat.

For the silver-containing and palladium surface acoustic, metal packaging transistors, integrated circuits with special cutting machine pin chips were cut out of the metal case a chip, an integrated circuit solution to extract the valuable metals containing aluminum electrolytic capacitor for high-rolling after the dry , after crushing the direct smelting of aluminum metal, for Zener diode, varactor part, such as glass sealing components, plastic light-emitting tube was refine valuable metals after compacted crushed, for circuit board use acid leaching then by liquid electrolysis produce electrolytic copper, palladium-containing circuit boards (double-sided circuit board containing basic palladium, palladium as copper substrate contained in a wire guide hole) reuse acid leaching of palladium, and then extract palladium.

1. After processing waste water emissions remain the same;

2. The recycle rate of gold,sliver,platinum,palladium can get more than 97-99%;

3. The purity of the precious metal can get 99.99%;

4. Full Automatic,saving the labor cost;

5. The process is short, use the hydro metallurgical without cyanogens technology, reduce pollution to the environment.

| Model | Capacity(Kg/Day) | Total Power(Kw) | Recycle Rate | Purity |

| PMR-100 | ≤100 | 135 | ≥98-99% | ≥99% |

| PMR-300 | ≤300 | 315 | ≥98-99% | ≥99% |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.