200-5000 Kg/H

Medicine Blisters, Food Packaging Bags, Toothpaste Tube, Al-plastic Combined Caps, etc.

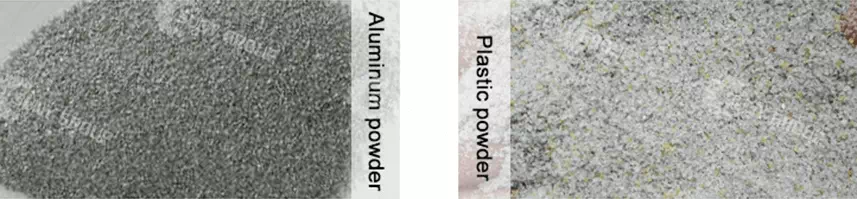

Aluminum Powder, Plastic Powder

SEND EMAIL: sunymachine@gmail.com

Aluminum Plastic Separator is mainly used for all kinds of aluminum tubes, aluminum-plastic bottle caps and other aluminum plastic products separation recycling.

The Aluminum Plastic Separator is designed by combing with the domestic and international advanced technology. The equipment adopts the advanced physics recovery process, the developed crusher and high pressure electrostatic separation equipment can help you get 99% metal recovery rate, and the metal purity can reach to more 97%.

All kinds of aluminum-plastic materials, Such as Medicine capsules plate, Medical blister, Aluminum composite panel, Food packaging bags, Tooth paste tubes, Aluminum and plastic combined caps, Leftover and pieces of Aluminum plastic board, etc.

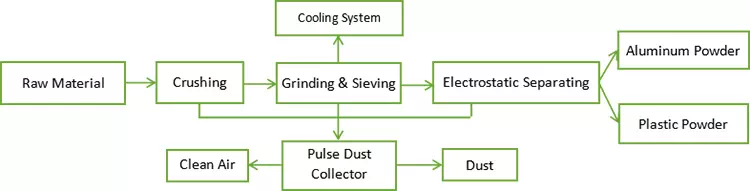

Firstly, by hook the car send a lot of materials into crusher, repass secondary crushing and tertiary grinding powder decomposition, and then through the sieve after the decomposition of the finished material through six roller electric machine one-time separation, separation of plastic and metal.

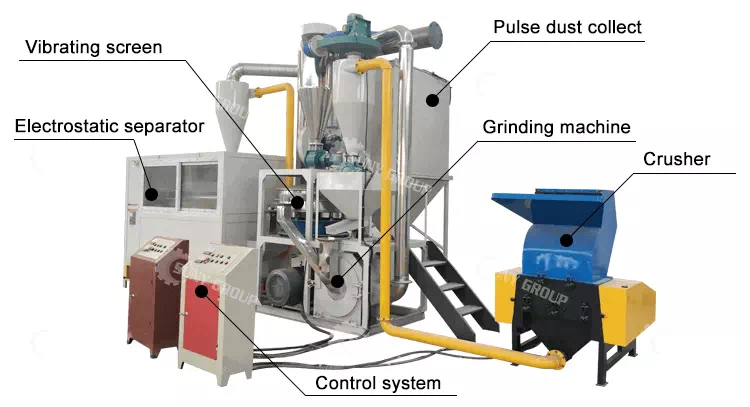

Crusher

The cutter stand is designed as a step-shearing style which can resolve the force bored by cuttings, and increase the force of cutting greatly.

The crushing room use noise arrester, to lower noise. Knife holder materials is high quality steel, rigid reasonable, not easy to broken or wear.

Grinder

1. Adopted the new design special bearings, to achieve the high roating speed;

2. Convenient to install and maintence, only need to open the door to clean;

3. Completely sealing when grinding, no dust pollution;

4. The mesh sizes can be adjusted, from 10mesh to 120 mesh, and easy to adjust the grinding gap;

5. The grinding machine adopted the wind cooling together with water cooling system;

6. New abrasive disk design, high capacity, good Wear Resistance, the service life is two times longer than the common abrasive disk.

Electrostatic Separator

Electrostatic separator can implement separation materials within a device separating the function of the extracted twice, can make the metal separation twice, also can make plastic sorting twice, higher purity. Equipment low consumption, low noise, high output, no dust and environmentally friendly.

Pulse Dust Collector

1. High efficiency of dust removal; dust particle with a diameter more than 0.3 micrometers can be gathered, and the dust collection efficiency is up to 99%;

2. Flexible use; the processing air volume can be from millions of cubic meters to hundreds of thousands of cubic meters per hour; it is a small unit which can be directly installed nearby the indoor machine, and can be also made into large dust collector;

3. With simple structure; working stably and easy maintenance.

PLC System

Controlled by PLC. Continuous feed, intelligent operation, automatic alarm make it easy to operate and save your time and effort, to ensure the stable operation of the equipment.

1. All the process is physical separation, without heating, burning, water and chemical, no smoke, waste water emissions, truly green separation, it won't cause any secondary pollution;

2. The process low cost, high efficiency and separation rate can be reached 99%;

3. The production line is automatic, saving labor; just one or two person is enough for operating machine;

4. This production line is used widely, Production line installation is convenient, has a variety of assembly method, can adapt to different venues;

5. Use the water cooling and wind cooling turbo type grinding machine, make the grinding efficiency higher, and process more kinds of raw materials.

| Model | Capacity(Kg/H) | Total Power(Kw) | Overall Dimension(MM) |

| APR-300 | 200-300 | 125 | 9000*7500-5000 |

| APR-500 | 400-500 | 270 | 18000*9300*5000 |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.