400-2000 Kg/H

Air Conditioner Radiator, Car Radiator

Copper, Aluminum

SEND EMAIL: sunymachine@gmail.com

Radiator Recycling Machine is used to separate copper and aluminum of the discarded air conditioner radiator and car radiator.The raw materials can be put into the all-in-one machine directly, after crushing, it will using the Air separation system to make the copper and plastic suspended on the screen. Then it can separate the Copper from the plastic by weighting method and the friction force which produced by the Surface of the mesh.

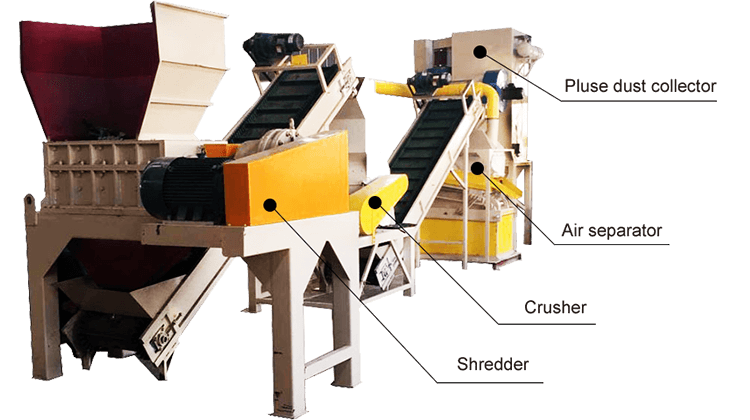

The material be shreddered and then crushed into 3cm particles. Through the magnetic separator, iron is separated. Then the airflow separator can sort the copper, aluminum, plastic. The equipment has features of new design, nice appearance, unique and large capacity. Whole plant PLC controlling, one time feeding, multi machine cooperated processing; with automatic shutdown device and the overload automatic alarm device. Successful development of the processing line, greatly liberate the productive forces, improve the metal recycling quality. The most important, it solves the problem of dust overflow effectively, reducing the pollution to air.

Radiator Recycling Machine can processing all kinds of large blocks of radiator(copper and aluminum water box) or motor rotor(with axle) ≤ 15cm.

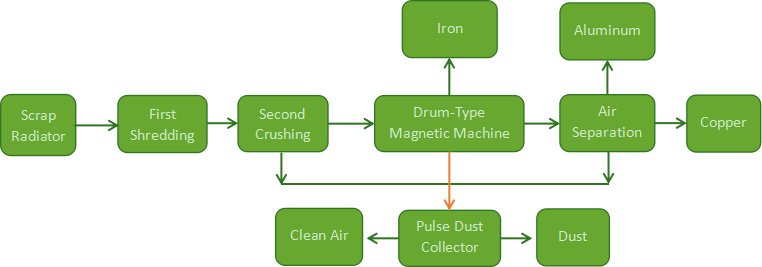

1. Crush the scrap radiator into particles (3 cm); 2. Second time crushing, the material will be crushed into much smaller size;

3. The iron will be selected out through the magnetic separator; 4. The aluminum and plastic will be separated out through the air flow separator;

5. Dust collector , ensure the cleanness and no pollution of the whole line.

1. The entire production line adopt PLC control, ensuring the equipment operation stability;

2. Simple structure, reasonable layout; large processing capacity, stable operation; durable, safe and reliable;

3. The shredder adopts two axes of the double roller design, with advantages of low noise, large torque, and large crushing chamber etc;

4. The shredder adopts tool steel, made by a special processing technology, wide application ranges. it combines cracking, tearing, and extrusion crushing, It applies to shredder different raw materials easily;

5. Magnetic separation equipment adopts strong magnetic drum separator, with sorting rate of 99%;

6. Pulse dust removal system inhibits the dust overflow in 99% efficiency, in full compliance with national environmental requirements "air pollutant discharge standards" GB16297-1996, no secondary pollution;

7. Using airflow sorting machine, with sorting rate of 97%.

| Model | Capacity(Kg/H) | Dimensions(mm) | Total Power(Kw) |

| SR-500 | 400-500 | 20000*8500*5500 | 139 |

| SR-1000 | 800-1000 | 24000*10000*5500 | 205 |

| SR-2000 | 1500-2000 | 28000*20000*5500 | 328 |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.