1000-10000Ton/Year

The raw materials for Upward Continuous Casting Copper Rod Making Plant should meet the requirements of GB/T467-2010 cathode copper No.1 standard copper Cu-CATH-2, Generally, cathode copper is commonly used, and pure copper is more than 99% waste copper.

Oxygen Free Copper Rods

SEND EMAIL: sunymachine@gmail.com

Upward Continuous Casting Copper Rod Making Plant is used to produce the long and bright oxygen-free copper rod with the diameter from 8 to 25mm. Large-length bright oxygen-free copper tube blanks and large-length bright oxygen-free copper slabs.

As a conductive material with high conductivity and low oxygen content, the oxygen-free copper rod is widely used in wire, cable, electromagnetic wire and other industries.

The raw materials for Upward Continuous Casting Copper Rod Making Plant should meet the requirements of GB/T467-2010 cathode copper No.1 standard copper Cu-CATH-2, Generally, cathode copper is commonly used, and pure copper is more than 99% waste copper.

Long and bright oxygen-free copper fod with the diameter form 8 to 25mm. Large-length bright oxygen-free copper tube blanks and large-length bright oxygen-free copper slabs.

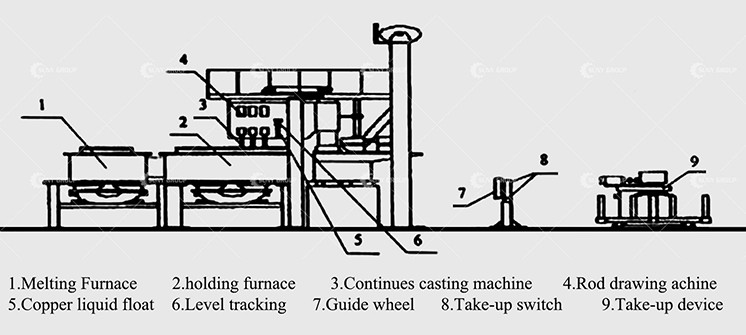

The Upward Continuous Casting Copper Rod Making Plant is mainly composed of melting furnace, heat preservation furnace, drag, crystallizer, speed regulating device, winding machine, cooling water system, electrical system.

1. Cathode copper is directly added to the melting furnace and melted into a liquid by power frequency induction;

2. After melting, the copper liquid will automatically and smoothly overflow into the intermediate holding furnace through the transition chamber;

3. The copper liquid has a stable reduction process by the covered surface of charcoal;

4. After the reduction, the copper liquid is rapidly crystallized into a cast rod through a crystallizer through the continuous casting machine in the holding furnace;

5. Every casting rod is equipped with a controller and a torsion bar machine.The casting rod is led from the continuous casting machine to the controller and the torsion bar through the regulating wheel device to form a circle. After the completion of the circle, the casting rod is cut and hoisted away for the next process.

1). Control oxygen content to eliminate copper rod hollow core technology;

2). Low energy consumption, single ton energy consumption is 20% lower than similar domestic equipment;

3). Removable sensor, flexible maintenance, short maintenance time;

4). Computer control, servo drive system, man-machine interface;

5). Fully automatic control of rewinding and arranging wire, single reel rewinding weight above 3 tons;

6). Charge with the highest temperature tolerance;

7). Our company independently researched furnace material, temperature resistance level is 1790 degrees, and the temperature resistance level is much higher than 1300 degree temperature resistance level of other manufacturers, so that the service life of the furnace is improved.

Our company can offer you whole processing solution for the copper, such as copper separator, copper electrolysis, copper bar production line etc, and we will offer you the professional installing and training service, to help you to build a perfect copper recycling factory.

| Model | Overall Dimension(MM) | Power(KW) | Capacity(Ton/Year) |

| CUC-1000 | 15000*6000*6500 | 100 | 1000 |

| CUC-3000 | 24000*6000*6500 | 250 | 3000 |

| CUC-5000 | 30000*6000*6500 | 350 | 5000 |

| CUC-8000 | 35000*6000*6500 | 400 | 8000 |

| CUC-10000 | 40000*6000*6500 | 550 | 10000 |

| Copper Rod :Meet the national standard/T3952-2008 standard | |||

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.