20-100set/h

Refrigerator, air conditioner, washing machine and other household appliances

Iron copper aluminum plastic etc.

SEND EMAIL: sunymachine@gmail.com

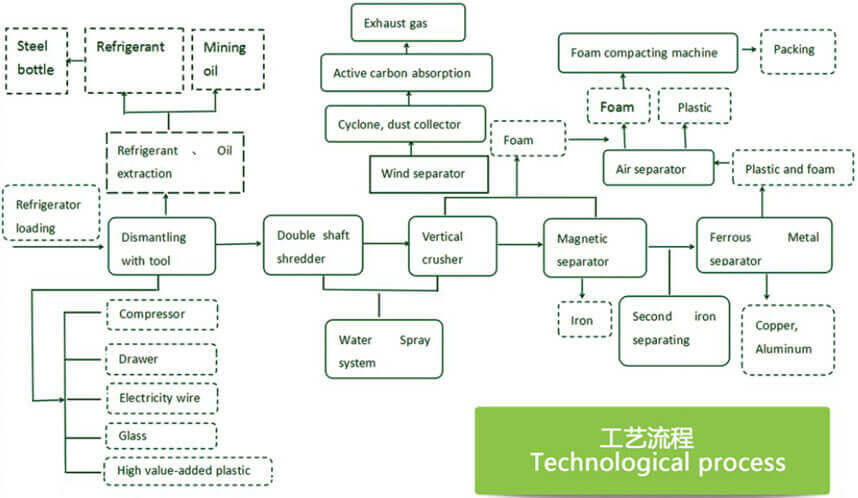

This production line is used for dismantling and recycling of refrigeration equipment such as air conditioners, refrigerators and washing machines. The equipment includes pretreatment station, fluorine pumping station, primary machine crushing, secondary crushing and separation, resource classification and

recovery device, etc

Equipment recovery rate:

iron recovery rate(% by weight): ≥99%%

Copper-aluminum recovery rate(% by weight): ≥97%

plastic sorting rate(% by weight): ≥ 97%(<3% of="" foam="" in="" recycled="" plastic="">

Noise and particulate matter emission meet the relevant national standards(reference standards(reference standard:)GB12348-2008,GB16297-1996);

The residual refrigerant in that compressor is collect by a refrigerant recovery device specially arranged in the pretreatment line and is centrally store in a pressure-resistant steel cylinder; Sorting compressor, easy-to-dismantle plastic, partition board and sorting, putting the box into primary crushing equipment at one time; Materials generated after primary crushing are automatically ransferred to secondary crushing and separation, and then automatically transferred to a sorting system to sort and recover iron, copper, aluminum, plastic and the like, and polyurethane foam is irectly separated into an independent processing system for volume reduction and packaging treatment. The tail gas in the treatment process is discharged into the atmosphere after bag dust removal and activated carbon adsorptio.

1.Double-shaft shredding and hummer crusher are combined. The unique process combining multiple sorting methods can realize the overall processing and sorting of refrigerators.

2.Environmental protection measures are perfect, no waste water is generated, and waste gas and noise meet the national safety standards.

3.The safety performance is good. Video monitoring and whole machine linkage control are adopted to ensure the safe and stable operation of the equipment.

4.High degree of automation, realizing one-key control of the whole line.

5.The polyurethane foam can be recycled after being crushed, and does not need to bear expensive disposal costs.

| Model | Power | Capacity(Set/H) |

| HA-20 | 176KW | 20-40 |

| HA-40 | 275KW | 40-60 |

| HA-60 | 500KW | 60-80 |

| HA-80 | 680KW | 80-100 |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.