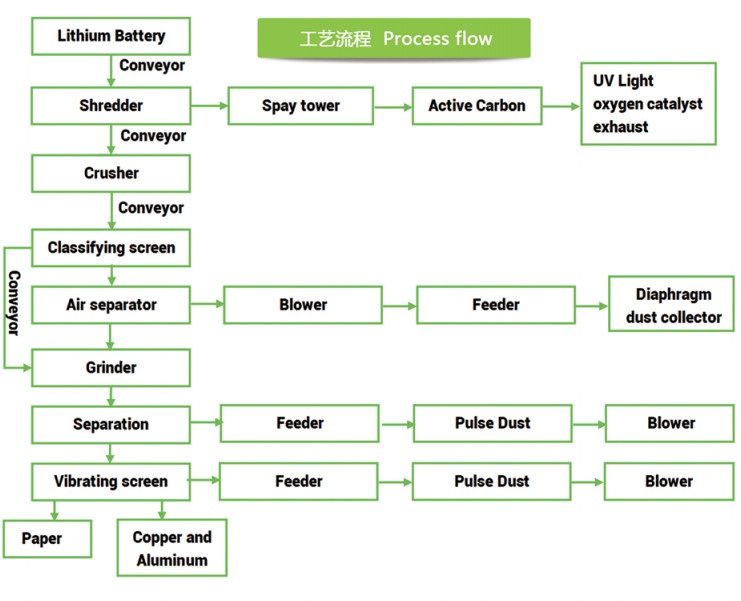

The scrap lithium battery is sent to the Class A shredder by the conveyor for shredding. The shredded material is sent to the secondary multi-blade crusher through the conveyor for the first crushing, and the material after the second crushing enters the conveyor. At the same time, a magnetic separation equipment is set up in the machine to separate the iron in the material. The sorted materials are sent to the air-flow sorting machine by the conveyor, the positive and negative diaphragm paper is separated by the induced draft fan and the cyclone, and the sorted positive and negative pieces are sent to the three-stage crusher For fine crushing, the material is crushed to about 20 mesh. The pulverized material enters the cyclone separator through the negative pressure system for dust filtration, and passes through two airflow sorting, so that materials of different densities are layered, and then the positive and negative materials are mixed with copper, aluminum, nickel and other materials. And all the ultra-fine dust is brought into the pulse dust collector by the negative pressure system for collection. The filtered exhaust gas will continue to be sent from the negative pressure system to the exhaust gas treatment equipment for air purification, so that it will meet the national emission standards before being discharged at high altitude.

Cobalt, lithium, copper and plastics in waste lithium batteries are precious resources and have a high recycling value. Therefore, scientific and effective treatment of waste lithium batteries not only has significant environmental benefits, but also has good economic benefits. Lithium batteries are mainly composed of outer shell, positive pole, negative pole, electrolyte and diaphragm. The positive pole is formed by coating lithium cobalt oxide powder on both sides of the aluminum foil current collector by PVDF which has a bonding effect; the negative pole structure is similar to the positive pole, which is composed of carbon powder bonded to both sides of the copper foil current collector. At present, researches on the recycling of waste lithium batteries are mainly focused on the recovery of valuable metals, cobalt and lithium, and there are few reports on the separation and recovery of negative materials.

Copper (with a content of about 35%) in waste lithium batteries is an important and widely used raw material for production. The carbon powder adhered to it can be used as additives such as plastics and rubber. Therefore, the effective separation of the negative components of the waste lithium battery will promote the realization of the limited recycling of the waste lithium battery and eliminate its corresponding environmental impact. Commonly used waste lithium battery recycling methods include hydrometallurgy, pyrometallurgy and mechanical physical method. Compared with wet method and fire method, mechanical physical method does not require the use of chemical reagents, and has lower energy consumption. It is an environmentally friendly and safe method.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231