The waste aluminum composite panel recycling market has begun to pick up, the international aluminum price has continued to rise, aluminum metal materials have been popular, and even aluminum metal-related industries have improved. Waste aluminum composite panels are widely used in indoor and outdoor decoration, box packaging, outdoor advertising, refrigerated transport truck boxes, etc. The annual scrap volume plus the volume of leftovers is still huge.

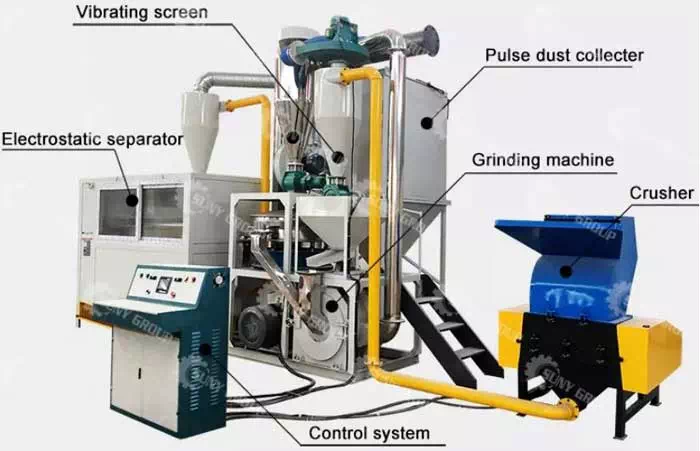

Structure diagram of aluminum-plastic separator

For the recycling of waste aluminum-plastic panels in the past few years, most people used the aluminum-plastic panel separator for separation. The aluminum-plastic panel separator is commonly known as the "baking machine". The cost of aluminum composite panel is at least 400-500 yuan. With the deepening of environmental protection, the use of baking machine for aluminum-plastic separation has to accept the impact of shutdown and rectification. The plate baking machine uses the effect of high temperature to separate the aluminum and plastic, and there is a large amount of carbon emissions in the processing process, which is not in line with the current environmental protection policy. Affected by this, the baking machine will also enter the end of the era.

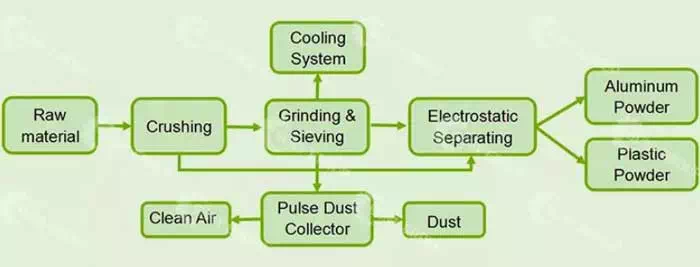

Working flow chart of aluminum-plastic separator

The environment-friendly aluminum-plastic panel separation equipment is a complete set of waste aluminum-plastic panel separation production line. The combination of electrostatic separation, pulse dust removal and other processes realizes the sorting and separation of aluminum and plastic materials for aluminum-plastic panels. The whole production process of the whole set of aluminum-plastic board separation equipment is connected with the pulse dust collector. Because the method of physical dry crushing and separation is adopted, the whole production process is environmentally friendly and pollution-free, and there is no waste water and smoke emission. This is very important and realizes the environmentally friendly separation of waste aluminum-plastic panels. Long-term development and strong sustainability. It is for this reason that the users who used the plate baking machine in the past have abandoned the previous operation of the plate baking machine and transformed it into an environmentally friendly aluminum-plastic plate separation equipment that is more in line with environmental protection requirements. After all, long-term development can only obtain corresponding economic benefits.

The above is a comprehensive analysis of the replacement of aluminum-plastic board separation equipment for the baking machine. The previous generation of the baking machine will eventually be replaced by the new aluminum-plastic board separation equipment. If you have more places to consult, please feel free to contact us.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231