With the widespread use of solar panels, we are also faced with the increasingly prominent issue of recycling. Currently, only about 10% of solar panels, like in the United States, are recycled, mainly because the cost of recycling is much higher than just throwing them away. However, it is predicted that by 2050, the value of materials in retired solar panels could be as high as $20 billion. This means that the development of economically viable solar panel recycling technologies is becoming particularly important.

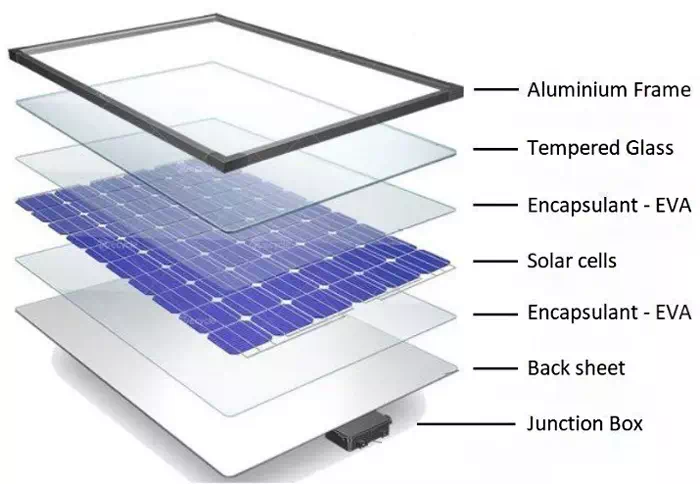

Solar panels have a sandwich-like structure with a solar cell in the center. Most commercial solar panels use silicon as a semiconductor to convert light energy into electricity. Each cell is covered with thin strips of metal, usually silver, which are interlaced across the surface of the silicon crystals to transmit power into the panel's copper wires. The solar cells are wrapped in a layer of clear plastic EVA, topped with a layer of glass, and the back is covered with different types of plastic, such as PET. The entire structure is surrounded by an aluminum frame, a complex layering that both protects the cells from the elements and allows sunlight to pass through, but it also makes the solar panel difficult to disassemble at the end of its life.

To combat this problem, SUNY GROUP has developed a comprehensive end-of-life solar panel recycling line that efficiently extracts valuable materials such as silver and silicon from old solar panels, making the recycling process economically attractive.

The recycling process consists of the following steps: first, removal of the frames and junction boxes; then, mechanical separation of the glass and wafers; and finally, purification of the silicon cells and specialty metals such as silver, tin, lead, and copper using separation technology.

The advantage of mechanical recycling is its efficiency and simplicity. Compared to chemical recycling, mechanical recycling does not require complex chemical processing and is therefore more straightforward. In addition, the equipment used in the mechanical recycling process often includes shredders and magnetic separators, which can process large quantities of solar panel waste quickly and efficiently.

Another advantage of mechanical recycling is its environmental friendliness. Since it does not involve the use of chemicals, mechanical recycling reduces the amount of pollution that may be caused to the environment. In addition, this method enables the recovered materials to be reused in the manufacture of new solar panels or other products, realizing the recycling of resources.

With the large-scale retirement of solar panels around the world, there is an urgent need to develop sustainable and economically viable solar panel recycling technologies, and SUNY GROUP has been working with many partners in the U.S., Europe, Thailand, Australia, and other countries and regions to help them solve the problem of recycling end-of-life solar panels. If you are interested in this or have related needs, please feel free to contact us, we will be happy to provide you with advice and support.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231