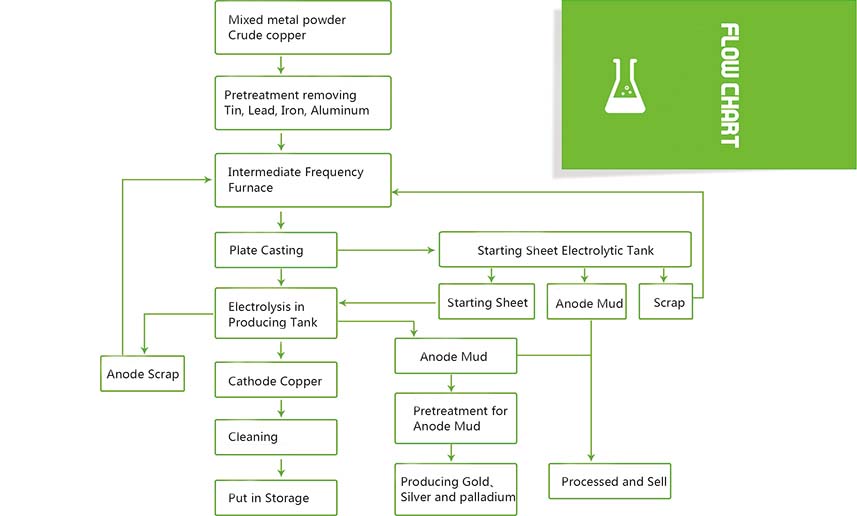

The blister copper (containing 99% copper) is pre-made into a thick plate as the anode, the pure copper is made into a thin sheet as the cathode, and the mixed solution of sulfuric acid (H2SO4) and copper sulfate (CuSO4) is used as the electrolyte. After electrification, copper dissolves from the anode into copper ions (Cu) and moves to the cathode. After reaching the cathode, electrons are obtained and pure copper (also known as electrolytic copper) is precipitated at the cathode. Impurities in blister copper, such as iron and zinc, which are more active than copper, will dissolve together with copper as ions (Zn and Fe). Since these ions are less likely to be precipitated than copper ions, the precipitation of these ions on the cathode can be avoided as long as the potential difference is properly adjusted during electrolysis. Impurities less reactive than copper, such as gold and silver, are deposited on the bottom of the cell. The copper plates produced in this way, called "electrolytic copper", are of extremely high quality and can be used to make electrical products.

Electrolytic copper is a widely used metal. It has unique advantages in electrical conductivity, potential conductivity, tensile strength, extensibility, corrosion resistance, fatigue resistance, etc. Electrolytic copper is very closely related to human beings. The non-ferrous metals are widely used in electrical, light industry, machinery manufacturing, construction industry, national defense industry and other fields.

Key equipment of electrolytic cathode copper production line

1. Special lifting equipment for copper electrolysis

Copper electrolysis automatic crane and spreader; automatic crane 2mm high-precision positioning; special driving;

2. Robotic cathode stripping unit

Arrangement and distance device; transfer trolley device; washing system; rapid air drying; cathode stripping device; cathode plate perpendicularity detection device; cathode copper plate conveying, stacking and packing device;

3. Residual electrode washing unit

Automatic cleaning system; stacking device; fully enclosed flip structure;

4. Anode shaping unit

Anode copper; anode plate conveying mechanism; shaping machine; straightening earphone; milling earphone; anode plate discharging machine; high-speed milling technology; traverse conveying vehicle;

5. Permanent stainless steel cathode plate

316L stainless steel plate; conductive rod; insulating clip edge strip;

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231