Electrolytic copper can be divided into two grades: high-purity electrolytic copper (Cu-CATH-1) and standard electrolytic copper (Cu-CATH-2). The purity of electrolytic copper is extremely high, and the copper content can reach 99%. Electrolytic copper is a copper foil formed by adsorbing copper ions on a substrate by electrolysis. Electrolytic copper can use oxygen-free copper, scrap copper, etc. as raw materials. How many steps are there in the electrolytic copper technology?

The existing waste copper recycling process has problems such as long process flow, low recovery rate, large investment, high energy consumption, low utilization level, and large environmental pollution. Therefore, research and development of waste copper direct electrolysis without smelting casting process Refining the clean production process has become an urgent task.

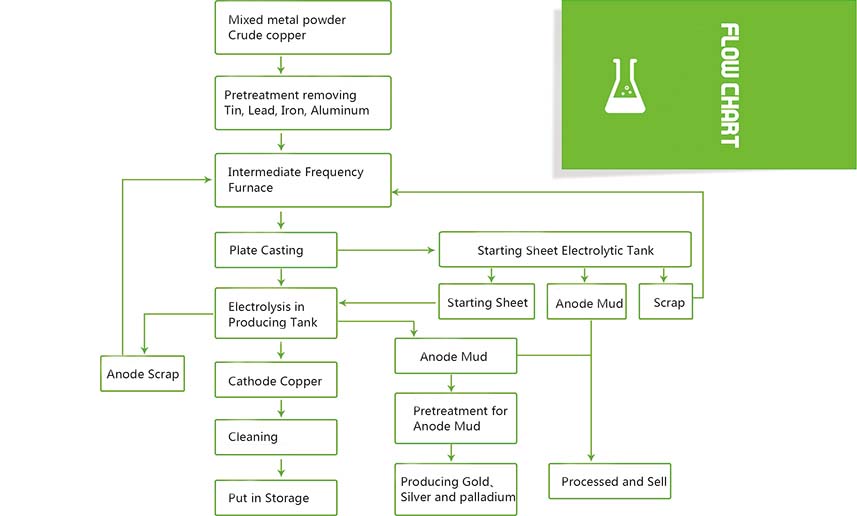

The clean production process of direct electrolytic refining of scrap copper is based on scrap copper as raw material:

1. Put the raw material into the anode frame as the anode, and use the permanent stainless steel cathode plate or pure copper sheet as the cathode.

2. Use acid copper sulfate solution as electrolyte for direct electrolytic refining of waste copper.

3. During the electrolysis process, the copper on the anode loses two electrons to form -2-valent copper ions into the solution, while the precious metals and some metals are insoluble and become anode slime and precipitate at the bottom of the electrolytic cell.

4. The -2valent copper ions in the solution are preferentially precipitated on the cathode

5. Other base metals with negative potential cannot be precipitated on the cathode and remain in the electrolyte to be removed when the electrolyte is regularly purified.

Therefore, electrolytic refining can obtain high-grade electrolytic copper and anode slime enriched with precious metals.

During the copper electrolysis process, the content of copper and impurities in the electrolyte gradually increases, the content of additives accumulates, and the content of sulfuric acid gradually decreases, so that the composition of the electrolyte deviates from the required condition control range. Therefore, it is necessary to periodically and quantitatively extract the electrolyte for purification treatment, and replace it with an equal amount of new liquid to adjust the composition of the electrolyte; at the same time, valuable metal impurities are also recovered to ensure the normal operation of electrolytic refining.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231