Waste lithium batteries contain a large number of non-renewable and high economic value metal resources, such as cobalt, lithium, nickel, copper, aluminum, etc. If the waste or unqualified lithium batteries can be effectively recycled, it will not only reduce the environmental impact of waste batteries pressure?

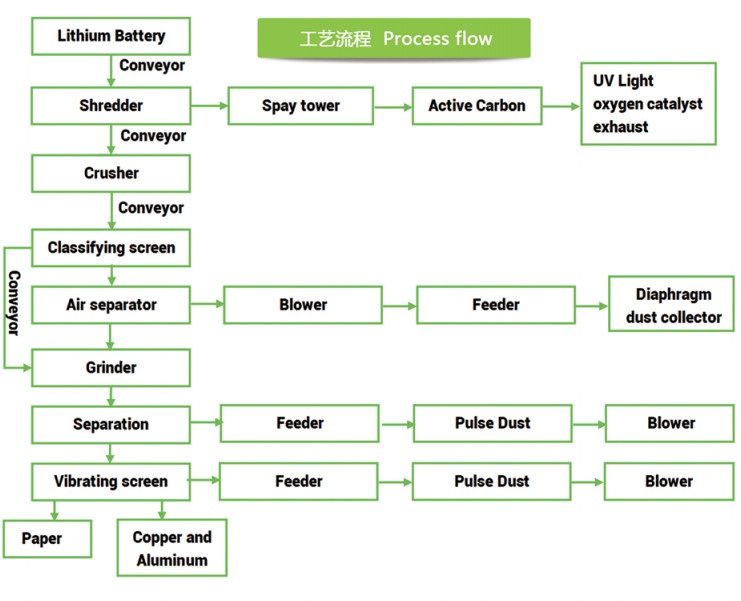

After the waste lithium-ion battery is discharged, it is subjected to primary crushing treatment. Before sending it to the next process, it needs to be screened. If it does not meet the size requirements, it will continue to be crushed. After the primary crushing treatment, it will be crushed again. Continue crushing if the size requirements are not met.

In the air separation treatment, the diaphragm is sent out by the wind. The gas in the air separation treatment is subjected to pulse dust removal treatment. The generated powder is sent to S6 for treatment, and the gas is sent to S7 for treatment. The treated material is subjected to magnetic separation treatment to separate the magnetic material. .

Lithium battery recycling process

The remaining small amount of diaphragm, electrolyte, binder and other organic substances are harmlessly carbonized by low-temperature oxygen-lean carbonization, which can reduce the oxidation degree of copper and aluminum, and the carbonized material is cooled.

The cooled material enters the powder sorting system to separate the positive and negative black powder, and the remaining material is sent to the friction dispersing system to fall off a small amount of positive and negative powder attached to the copper and aluminum, and the treated material is dispersed by friction Under the condition of wind generated by the system itself, it is transported to the coarse and fine separation system to separate the positive and negative electrode powder and copper and aluminum sheets, and the separated positive and negative electrode powder.

The remaining materials are basically a mixture of copper and aluminum. In the ball mill subsystem, the copper and aluminum sheets are kneaded into balls, and then sent to the copper and aluminum sorting subsystem, where the difference in specific gravity is used to separate copper and aluminum.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231