The increase in electronic waste is placing huge pressure on the environment, and one of the most important components is circuit boards. Circuit boards contain many valuable metals and toxic materials, so efficient recycling and disposal of circuit boards becomes critical. So how to recycle circuit boards?

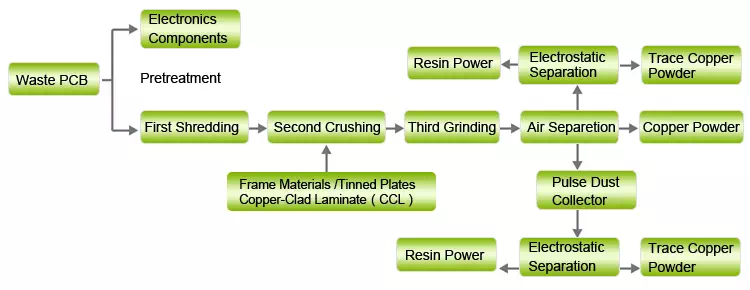

First, let’s take a look at the mechanical processing process of circuit board recycling equipment. The whole process can be divided into four main stages: pretreatment, crushing, separation and extraction.

The main purpose of the preprocessing stage is to remove external accessories on the circuit board, such as plastic casings, metal casings, etc. This can be done by manual disassembly or automatic mechanical disassembly. Automated mechanical disassembly equipment typically uses methods such as cutting, stripping, and crushing to quickly and efficiently separate circuit boards from their accessories.

Next comes the crushing stage. At this stage, the circuit boards are fed into a crusher for fine crushing. A shredder usually uses tools such as blades or hammers to crush circuit boards into small particles. This process is designed to increase the surface area to facilitate subsequent separation and extraction operations.

PCB Recycling Process

The separation stage is one of the key steps in the circuit board recycling process. The circuit board fragments are fed into the separation equipment, where the metallic and non-metallic parts are separated by physical and chemical methods. Commonly used separation technologies include gravity separation, magnetic separation, air flow separation and liquid separation, etc. For example, gravity sorting can separate metals and non-metals based on their density differences through vibration or air flow. Magnetic sorting uses electromagnetic force to separate fragments containing magnetic materials from non-magnetic materials.

Finally, there is the extraction stage. After separation, the metal fraction requires further extraction and refining. This can be achieved by smelting, chemical leaching or electrochemical methods. Smelting is one of the most common extraction methods, in which metal fragments are heated to high temperatures, causing them to melt and separate out the valuable metal. Chemical leaching removes metals from debris using a solvent or acid solution. Electrochemical methods use electrical current and chemical reactions in an electrolyte solution to convert metal ions into metal deposits.

In addition to mechanical processing processes, sorting technology also plays an important role in circuit board recycling. Sorting technology can effectively separate different components in circuit boards based on different physical and chemical properties. This helps improve recycling efficiency and resource utilization.

One commonly used sorting technique is optical sorting. Optical sorting utilizes the differences in light reflection, absorption and transmission of different materials to identify and sort circuit board fragments through optical sensors. Depending on the properties of the material, metallic and non-metallic parts can be separated.

In addition, airflow sorting is also a common technology. Airflow sorting takes advantage of the density differences and shape characteristics of circuit board fragments to separate them through the action of airflow. The lighter non-metallic parts will be blown away by the air flow, while the heavier metal parts will be retained.

Magnetic sorting is another effective sorting technology. By applying a magnetic field, magnetic materials can be attracted or repelled, thereby achieving separation from non-magnetic materials. In circuit board recycling, magnetic sorting can separate fragments containing magnetic metal from non-magnetic parts.

In summary, the mechanical handling process and sorting technology of circuit board recycling equipment play a key role in the effective recycling and processing of circuit boards. Through stages such as pretreatment, crushing, separation and extraction, valuable metals in circuit boards can be extracted, and harmful substances can be separated and processed to achieve environmentally friendly circuit board recycling. Continuous innovation and improvement of mechanical processing technology and sorting technology will further improve the efficiency and sustainability of circuit board recycling, contributing to environmental protection and resource recycling.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231