Aluminum foil separator is an advanced equipment specially used to separate waste aluminum foil. This article will introduce the technical principle, advantages and characteristics of the aluminum-plastic separator and the economic benefits it brings.

Aluminum foil medicine board recycling

Technical principle of aluminum foil separator:

Aluminum foil is a common packaging material, made of thin and lightweight aluminum metal, which has excellent thermal conductivity and moisture resistance. However, many waste aluminum foils are often bonded with plastic films, and there are certain difficulties in traditional recycling methods.

The aluminum-plastic separator adopts advanced physical separation technology to separate waste aluminum foil and plastic film through a series of process steps. Its main technical principle includes the following steps:

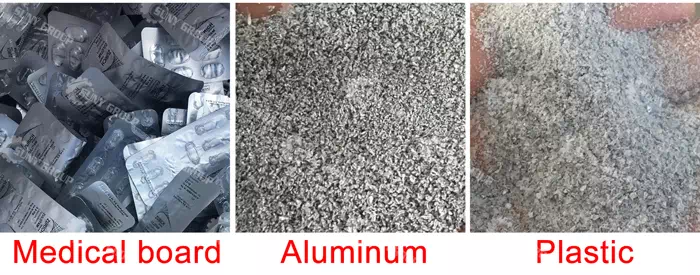

Crushing: The waste aluminum foil is processed by a pulverizer to make it into small particles suitable for subsequent separation.

Separation: Use the physical separation principle of the separator to separate the aluminum foil and plastic film. Separators usually use vibrating screens, air separators and other equipment to separate the two through different physical properties.

Regeneration: The separated aluminum foil can be regenerated through smelting and other regeneration processes to obtain high-quality aluminum for re-production.

The aluminum-plastic separator has the following significant advantages:

Aluminum plastic separation and recycling machine

Automation: The entire separation process is automated, reducing manual intervention and improving work efficiency.

Efficiency: The separator adopts efficient physical separation technology, which can quickly and accurately separate aluminum foil and plastic film, improving the separation efficiency.

Environmental protection: The aluminum-plastic separator adopts the principle of physical separation, without the use of chemicals, reducing environmental pollution.

Versatility: The separator can adapt to different specifications and types of waste aluminum foil, and has strong adaptability and versatility.

Cost saving: The separation of waste aluminum foil through the aluminum-plastic separator can save manpower and time costs, and improve the recycling rate of waste resources.

The application of aluminum-plastic separator has brought significant economic benefits:

Resource recycling: The aluminum foil separated by the aluminum-plastic separator can be recycled, which reduces the demand for primary aluminum resources and reduces production costs.

Reduce the cost of waste disposal: The application of the separator makes the disposal of waste aluminum foil more efficient and reduces the cost of waste disposal.

Energy saving and emission reduction: The recycling of aluminum foil reduces the exploitation of traditional ore resources, reduces energy consumption and environmental emissions, and meets the requirements of sustainable development.

The aluminum-plastic separator developed and manufactured by SUNY GROUP realizes the efficient separation of waste aluminum foil through advanced physical separation technology, and has the remarkable characteristics of automation, high efficiency and environmental protection. Its application not only brings resource recycling and waste disposal cost reduction, but also creates employment opportunities and has a positive impact on energy saving and emission reduction. With the continuous improvement of environmental protection awareness and the demand for sustainable development, aluminum-plastic separators have broad market prospects.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231