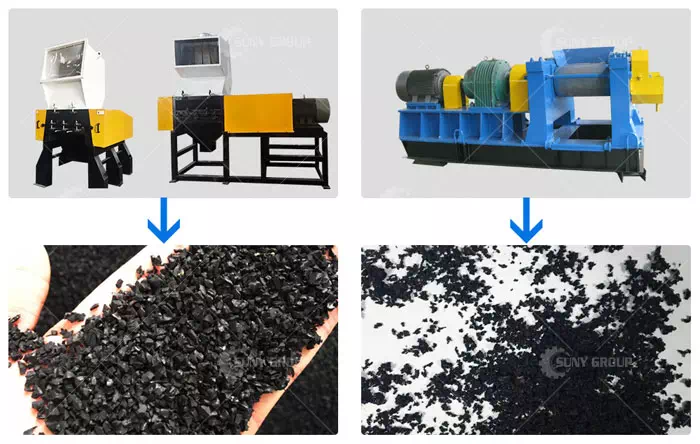

Waste tire rubber powder equipment is composed of waste tire decomposition equipment, rubber powder crushing, screening and magnetic separation conveyor unit. Through the waste tire decomposition equipment, the tires are first processed into small pieces of 3.5 cm square; then the rubber blocks are crushed and ground by the crushing unit XKP400/450/560 to obtain rubber powder and rubber particles mixed with steel wires; then the rubber powder is sieved The magnetic separation conveying unit completely separates the steel wire from the tire rubber.

The fine material screened out by two sieve beds through the belt conveying device is then passed through the magnetic roller, and the steel wire is separated by magnetic separation to produce pure rubber powder with a fineness of 10 mesh to 40 mesh (fineness is optional). The rubber powder that does not meet the required mesh fineness is returned to the pulverizer through the block conveyor for re-grinding. This circular grinding process is advanced in technology, does not require any chemical raw materials, no waste gas, no waste water, and low operating costs. The effect of magnetic steel wire separation is over 99.9%. Taking the XKP450 type as an example, the total installed power is 80KW, the average power consumption per ton of tires is about 200 degrees, and the output per hour is 200-400 kg (the fineness of the obtained rubber powder is different, and the output is also different. There are differences), and it is the best equipment for producing rubber powder from steel wire tires.

This set of unit is composed of main machine and auxiliary machine; it is a special equipment for processing waste tires (steel wire tires or wire tires) into rubber powder, and can also process waste rubber products into rubber powder.

Auxiliary equipment includes 3 sets of decomposition processing equipment: strip cutting machine, ring cutting machine, block cutting machine; 4 sets of powder making equipment: vibrating screen, conveyor, magnetic separation vibrating screen, feeding machine; magnetic separation of steel wire and rubber powder 1 set (2-track magnetic separation) and other components.

The main engine (rubber breaker) is mainly suitable for grinding tires, wire tires, steel wire tires (radial tires) and various miscellaneous rubber products, making them into rubber powder and reaching the required fineness (mesh number).

This machine mainly consists of an integrated base, frame, front and rear rollers, transmission gear, reducer, adjustment device, roller temperature adjustment device, safety switch and electrical control system.

The material of the roller iron is alloy chilled cast iron, which has high hardness and wear resistance. The roller temperature adjustment device can feed cooling water into the roller to adjust the roller temperature to meet the process requirements.

This machine is designed and installed with safety protection devices:

1. Electrical protection: When the equipment is overloaded, the equipment will stop.

2. Roller safety safety device: When the working pressure of the equipment exceeds the roller pressure momentarily, the safety safety sheet will break automatically. In order to protect the roller and other main parts (XKP-400 does not have this device), the machine runs more reliably and the maintenance cost is minimized. 3. The machine is equipped with a braking device

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231