In the field of metal recycling, waste aluminum-copper radiators have always been a type of material with high technical requirements in recycling and processing due to their complex structure and composite materials. Efficient recovery of copper and aluminum from these radiators depends not on manual dismantling, but on specialized, automated cutting and separation equipment. A mature aluminum-copper radiator cutting and separating machine can significantly improve processing efficiency and resource value while ensuring the purity of the recovered materials.

I. Working Principle of the Radiator Cutting Equipment

Aluminum-copper radiators are usually composed of tightly bonded aluminum fins and copper tubes, making complete separation difficult using traditional methods. A dedicated cutting machine uses high-strength alloy blades to perform directional cutting on the radiator, effectively breaking the bond between the copper tubes and aluminum fins. The equipment maintains stable feeding and even force distribution during the cutting process, preventing deformation of the copper tubes and reducing excessive fragmentation of aluminum chips, creating ideal conditions for subsequent separation. The entire machine adopts a closed structure design, ensuring safety and operational stability while maintaining cutting efficiency.

Aluminum Copper Waste Radiator Cutting and Separating Machine

II. Core Configuration of the Aluminum-Copper Separation System

The cut materials enter the separation system, where efficient separation of aluminum and copper is achieved through multi-stage mechanical sorting. The equipment is usually equipped with drum screens, vibrating screens, or specialized separation devices to perform precise screening based on the shape and density differences of the metals. For radiators of different specifications, the system can flexibly adjust processing parameters to ensure the integrity of the copper tubes and the cleanliness of the aluminum material. The stable separation structure not only improves the purity of the finished metal but also significantly increases the added value of subsequent smelting or reuse.

III. Advantages of the Complete Equipment in the Recycling Line

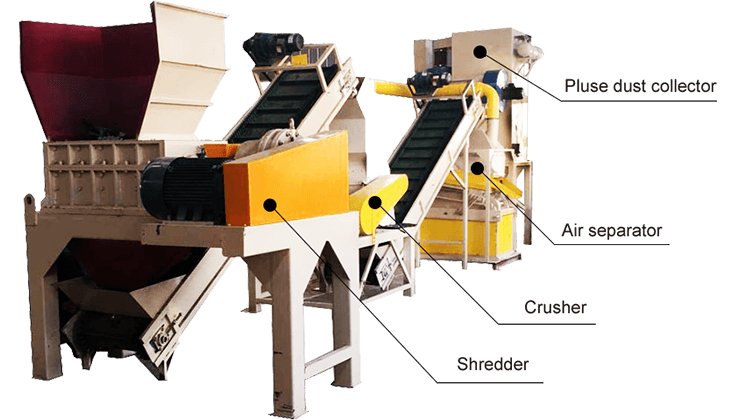

The aluminum-copper radiator cutting and separating machine can operate independently or be integrated with crushing, conveying, and dust removal systems to form a complete recycling production line. It features a high degree of automation, requires minimal manual intervention, and can operate continuously and stably, making it suitable for appliance recycling plants, metal recycling companies, and professional dismantling centers. Compared with traditional manual dismantling methods, this equipment offers significant advantages in efficiency, cost control, and safety, while also reducing the reliance on operator experience.

Through professional cutting and separation equipment, waste radiators are no longer a recycling challenge, but a high-value recyclable resource. A stable and efficient aluminum-copper radiator processing solution is becoming an important foundation for achieving large-scale and refined operations in the metal recycling industry.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231