800-5000kg/h

Coated paper, Kraft paper bag, Tetra pak, Combibloc, Paper-plastic composite woven bag

packed pulp, plastic film, aluminum foil

SEND EMAIL: sunymachine@gmail.com

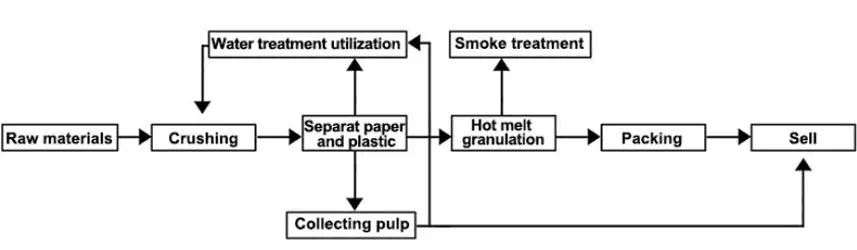

For paper-plastic composite materials, the tetra pak recycling paper-plastic sorting plant adopts the method of mixing with water and friction separation of the main shaft sieve plate. The production capacity and effect of the equipment have reached the high-end level in the industry.

Suitable for all kinds of paper-plastic composite materials, such as, Coated paper, Kraft paper bag, Tetra pak, Combibloc, Paper-plastic composite woven bag.

The final product is packed pulp, plastic film, aluminum foil (aluminum-containing composite material).

The paper-plastic sorting plant includes Four Main Single Machines(As your demands)

1. Paper Aluminum Separator

2. Pulp Filter

3. Pulp Dehydrator

4. Pulp Filter Press EquipmentPaper

Aluminum Separator:

Paper aluminum separator is the main equipment of the whole paper-plastic recycling production line. The working principle is that the motor drives the spindle to rotate at high speed. The spindle blade drives the material to move from the feeding end to the discharging end.

Pulp Filter:

In the pulping of waste paper, because of the different paper quality of waste paper, there is a large amount of slag. This machine can remove light and heavy sundries and decompose small pieces of paper in fibers, without blocking the sieve plate, and hard sundries will not hurt the sieve plate.

Pulp Dehydrator:

The basic working principle of the pulp dehydrator is: the particles rotate to a certain height with the drum,are thrown and fall by gravity, and are filtered through the screen to form a sieve.

Pulp Filter Press Equipment:

The basic working principle of the pulp dehydrator is: the particles rotate to a certain height with the drum,are thrown and fall by gravity, and are filtered through the screen to form a sieve.

| Model | Capacity(Kg/H) | Total Power(Kw) | Overall Dimension(MM) |

| PPR-1000 | 800-1000 | 430 | 33000*14000*5000 |

| PPR-3000 | 2500-3000 | 670 | 44000*14000*5000 |

| PPR-5000 | 4500-5000 | 1190 | 40000*30000*5000 |

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.