When it comes to lithium battery recycling, choosing the right machinery is critical to an efficient and sustainable operation. As demand for lithium batteries continues to rise, the need for effective recycling solutions becomes increasingly important. In this article, we will guide you in choosing the best lithium battery recycling machinery. We will also explore the relevant process principles and highlight the advantages and unique features of these recycling equipment.

Lithium battery recycling machinery uses a series of process principles to ensure efficient recovery of valuable materials while minimizing environmental impact. include:

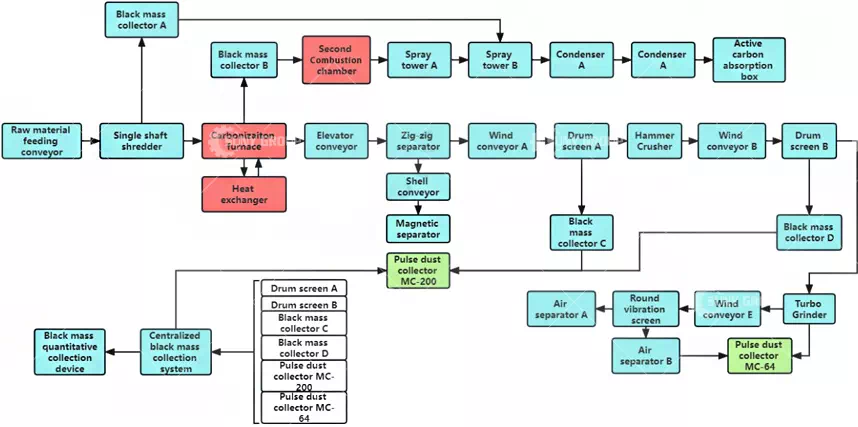

The latest lithium battery recycling process flow chart

1. Disassembly and separation: This machine uses advanced technology to disassemble the battery and separate its components. The process involves removing the casing, separating the electrodes, and isolating the electrolyte.

2. Mechanical crushing and thermal treatment: Recycling equipment utilizes mechanical and thermal methods to further separate and recover valuable materials such as lithium, cobalt, nickel and other metals. Techniques such as crushing, shredding and smelting are used to extract these materials for reuse.

d. Purification and refining: After the material is separated, it will undergo a purification and refining process to ensure its quality and suitability for reuse in battery manufacturing or other industries.

When choosing the best lithium battery recycling machine, consider the following benefits and unique features:

Lithium battery recycling equipment manufacturing workshop

1. High efficiency: Look for machinery with high processing capabilities to efficiently handle large quantities of lithium batteries. This ensures optimal utilization of resources and maximizes the recovery of valuable materials.

2. Appropriate sorting technology: Choose appropriate sorting technology equipment such as air flow sorting sieves and electrostatic sorters to achieve accurate identification and sorting of battery types. This increases the efficiency and effectiveness of the recycling process.

3. Safety measures: Make sure the machinery has safety features to handle hazardous materials and prevent accidents. This includes dust collection and gas extraction, fire suppression and personnel protection systems.

4. Environmental compliance: Choose recycling machinery that complies with environmental regulations and standards. Look for equipment that minimizes emissions, wastewater and waste generation throughout the recycling process.

5. Automation and control systems: Look for recycling machinery equipped with advanced automation and control systems. These systems optimize process efficiency, reduce human error, and provide real-time monitoring and data analysis for informed decision-making.

6. Consider the durability and ease of maintenance of the machinery. High-quality machinery should be durable and require minimal maintenance. This will save you time and money in the long run.

Choosing the best lithium battery recycling machinery is crucial to achieving efficient and sustainable operations. By understanding the principles of the process and considering the advantages and unique features of the equipment, you can make an informed decision. When choosing a machine, remember to prioritize high efficiency, excellent sorting technology, safety measures, environmental compliance, flexible automation. By considering these factors, you can ensure that the machinery you choose can meet your recycling needs and contribute to a more sustainable future.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231