The radiator copper aluminum separator stripping machine is an essential piece of equipment in the recycling industry. It is designed to separate and strip copper and aluminum from discarded radiators, allowing these valuable materials to be reused and repurposed. This machine offers numerous advantages over traditional manual separation methods, including increased efficiency, enhanced safety, and improved product quality.

Efficiency: The radiator copper aluminum separator stripping machine is capable of processing large volumes of radiators quickly and accurately. This increases the overall efficiency of the recycling process, allowing recyclers to handle greater volumes of materials in a shorter amount of time.

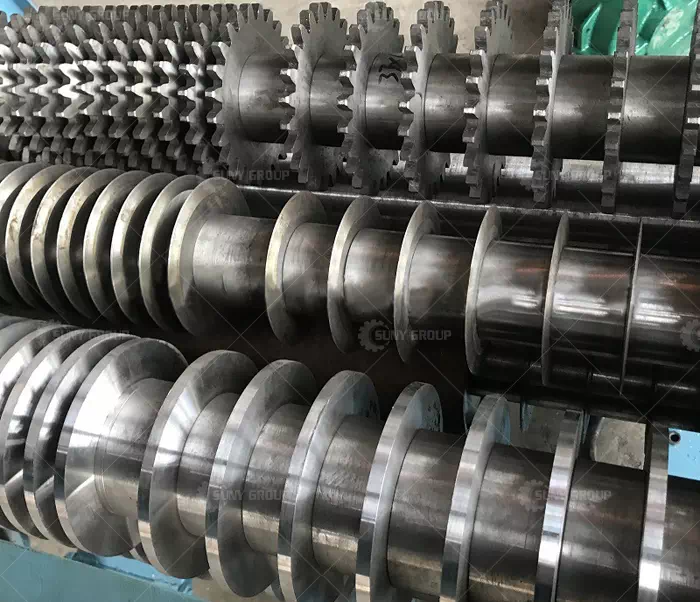

Internal structure of copper aluminum separator

Consistency: The machine ensures consistent separation and stripping of copper and aluminum from radiators, resulting in high-quality end products. This helps to maintain the reputation and customer satisfaction of recycling companies.

Reduction in Labor Costs: The use of a radiator copper aluminum separator stripping machine reduces the need for manual labor in the separation and stripping process. This translates to lower labor costs and increased profitability for recycling companies.

Improved Safety: By automating the separation and stripping process, the machine minimizes the potential for workplace accidents and injuries. This is particularly important given the hazardous nature of the materials being processed.

Radiator Copper Aluminum Separator

Versatility: The radiator copper aluminum separator stripping machine can be customized to handle different sizes and types of radiators, making it a versatile piece of equipment that can adapt to the changing needs of recycling companies.

Space-saving: This machine is designed to occupy minimal space in the recycling facility. It is compact and efficient, allowing it to be easily integrated into existing recycling lines.

Cost-effective: While the initial investment in the radiator copper aluminum separator stripping machine may seem significant, the long-term benefits such as increased efficiency, reduced labor costs, and improved product quality make it a cost-effective solution for recycling companies.

In conclusion, the radiator copper aluminum separator stripping machine is a vital piece of equipment that offers numerous advantages over traditional manual separation methods. By increasing efficiency, consistency, and reducing labor costs, it helps to improve the overall profitability of recycling companies. Moreover, the machine's versatility and safety-enhancing properties make it an essential investment for companies looking to process and recycle radiators in an efficient and responsible manner.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231