With the recent years data show that the waste lithium batteries continue to rise, then we have to put the recycling of lithium batteries how to deal with it? Waste lithium battery ladder use, then we recovered back the lithium battery disassembly will have how! Because lithium-ion batteries are recyclable, it is divided into metal and plastic parts that can be reused to make new products. It is vital to achieve the reuse of raw materials by disassembling and recycling used lithium batteries, which is the direction we have been working on. Currently, through our technology, the recovery rate of copper, aluminum, nickel, cobalt, and other core metals in waste batteries can reach more than 99.5%.

Lithium-ion battery treatment process

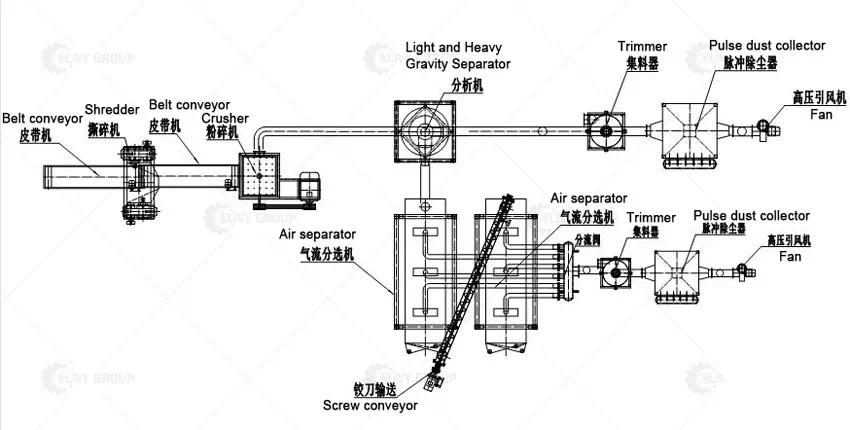

The recycling of waste lithium batteries with the current process waste batteries must be pre-treated first, then the battery shredding, crushing, shredding, separating diaphragm, shell and positive and negative fragments, through multiple crushing, wind selection, separation to get copper and aluminum mixed metal particles, to achieve the automated recycling of waste lithium batteries.

The lithium battery recycling process is simplified, with high output and high metal separation rate. The separation rate of waste lithium battery and black powder after crushing and sorting reaches more than 99% (according to the data assayed from the customer's site). Power battery in a large number of cobalt, nickel, manganese, lithium and other chemical and rare mineral materials, separation and purification, production into raw materials for the manufacture of batteries.

1. The range of applicable materials is relatively large;

2. Compact design concept saves space;

3. The operation console inspection system and maintenance platform are built for easy access to maintenance;

4. Continuous automatic production, can withstand more resistance and accumulate greater production effectiveness.

Lithium battery dismantling equipment, waste power battery recycling dismantling equipment for waste power battery diaphragm material efficiency, can be higher than other brands of more than 35%, can effectively improve the efficiency of dismantling and recycling. Power battery recycling production line not only caters to the current development trend of power battery recycling, effectively standardize the power battery recycling production line, construction assembly and acceptance requirements, but also well implement the construction policy of green environmental protection, energy saving and emission reduction, avoid power battery waste and promote the green intelligent ecological sustainable development of the industry.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231