In order to improve the use and processing performance of copper, it is necessary to remove impurities in blister copper, such as nickel, lead, arsenic, etc., and at the same time recover valuable metals, such as gold, silver, etc., which is the refining process of blister copper.

The principle of blister copper refining: Through the electrolysis of electrolyte solution, blister copper is used as anode, pure copper is used as cathode, and a solution containing copper ions is used as electrolyte, copper is dissolved from the anode and precipitated at the cathode. Impurities in blister copper, inert impurities do not dissolve, and become anode sludge and settle at the bottom of the electrolytic cell. Although active impurities dissolve at the anode, they cannot precipitate at the cathode. Therefore, copper with high purity can be obtained by electrolysis of the cathode.

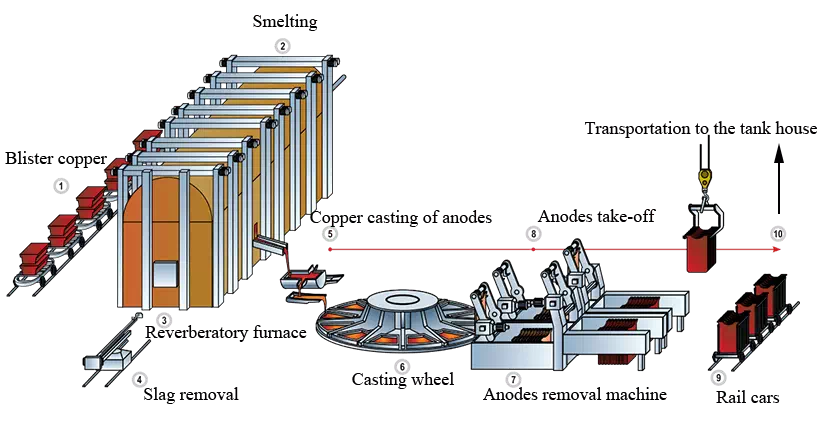

Main equipment for copper electrolytic refining:

Electrolytic Copper Refining Plant

(1) Electrolyzer

The electrolytic cell is the main equipment of the copper electrolysis workshop. It is a rectangular tank with anode plates and cathodes inside, and the cathode and anode are hung alternately. There are liquid discharge outlets and mud discharge outlets in the tank.

The electrolytic cell is generally constructed of reinforced concrete and lined with anti-corrosion resin, so that the cell body can not only support the cathode and anode, but also play the role of anti-acid. The electrolytic tanks are arranged sequentially on the supporting beams, and the beams are covered with insulating materials to prevent the tanks from conducting electricity with the ground.

(2) Cathode making unit

The function of this unit is to make cathodes from the copper peeled off from the titanium mother board after embossing, riveting ears (piercing rods) and flattening processing, and then arrange the cathodes for the crane to lift away.

Due to its unique functions, the cathode production unit needs to be produced by a professional manufacturer. During the design and manufacturing process of this unit, the thickness of the copper skin and the processing capacity of the rivet lugs should be considered.

(3) Anode processing unit

The function of this unit is to process the anode plates obtained from fire refining to meet the standards required by the electrolysis process. The working procedures of this unit are: flattening of anode plate surface, ear cleaning, ear pressing, anode plate row spacing, etc.

The quality of each oil pressure seal and the processing capacity of the anode plate should be fully considered during the design and manufacture of the anode processing unit.

(4) Electric copper washing unit

The function of this unit is to wash and dry the electric copper after leaving the tank, draw out the conductive rod, stack, pack and weigh the electric copper. Many copper electrolysis manufacturers in China do not use this unit, but rely on manual work to complete each function of the unit.

(5) Residue pole unit

The function of this unit is to wash, stack, pack and weigh the anode residues after leaving the tank, and then send the packed anode residues to fire refining for remelting. Due to the simple function of this unit, many copper electrolysis manufacturers in China do not use this unit, but rely on manual to complete the treatment of residual poles.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231