Power lithium-ion batteries have become the first choice for electric vehicle power. Once electric vehicles are mass-produced, it will undoubtedly bring great development opportunities to the lithium-ion battery industry. With the application of lithium-ion batteries in electric vehicles, the consumption of lithium-ion batteries has increased sharply, which will lead to a substantial increase in the use and consumption of lithium resources in the world, and the consumption of non-renewable metal resources is also considerable. Therefore, the environmental protection recovery and resource reuse of power lithium-ion batteries can not only greatly save lithium resources, but also be conducive to environmental protection and sustainable economic and social development, resulting in huge environmental benefits and significant economic and social benefits.

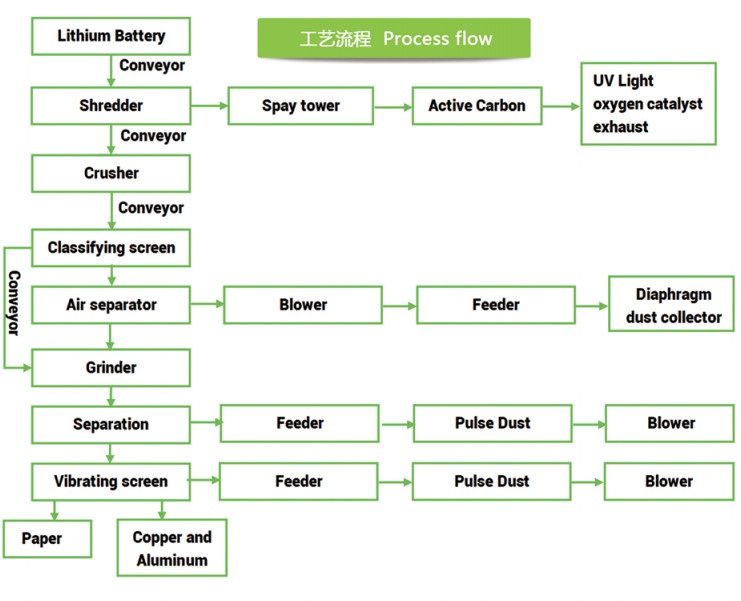

Waste lithium battery treatment equipment is an effective solution for the recycling and reuse of waste lithium ion batteries. The whole waste lithium battery recycling process has no harmful exhaust gas emissions, and realizes environmentally friendly recycling of waste lithium batteries. In order to achieve no exhaust gas emissions, the following process measures are mainly adopted:

1. Set up a vacuum heating/hydrolysis deliquoring device, which has outstanding functions of water spraying, hydration decomposition and heating and pyrolysis of lithium hexafluorophosphate

2. Crushing: The vacuum deliquored clean battery fragments are sent to the crusher through the screw feeder, and further broken into smaller fragments;

3. Air flow sorting: the separator paper in the crushed lithium battery is screened out by the air flow sorting machine, and other materials are screened out and enter the shell sorting conveyor;

4. Shell sorting: Shells are generally divided into iron shells and stainless steel shells. There are two methods: 1) Magnetic sorting method, using the magnetic conductivity of the iron shell, to set a magnetic roller at the discharge port of the conveyor, and the iron shell After being adsorbed by the magnetic roller, it falls into the blanking collection hopper; 2) Gravity air separation method: adopt specific gravity air separation for the non-magnetic stainless steel shell, set a blower at the lower part of the discharge port of the conveyor, and adjust the wind power and falling height of the blower. The material collection hopper is set at the lower part of the stainless steel shell with a heavy specific gravity, and the pole pieces and plastics with a light specific gravity are blown into the next-stage pulverizer.

5. Pulverization: further pulverize the debris and pole pieces separated from the shell into fine particles and send them to the analyzer.

6. Gravity powder separation: use the analyzer to disperse the materials entering the interior, adjust the air volume and wind speed, use the particle weight, the pole piece particles are collected from the bottom and sent to the next stage, and the powder enters the second pulse dust removal device from the top;

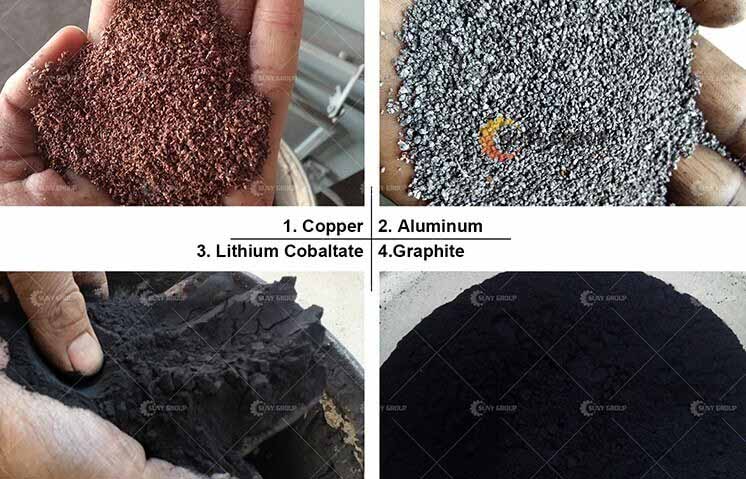

7. Separation of copper and aluminum metals: The large copper and aluminum particles are separated from the top outlet of the rocking screen by the swing screen, and the powder with light specific gravity is separated from the bottom and sent to the black powder collection bin, and the middle part of the specific gravity is inseparable and sent to the grinder , Rotary vibrating screen, and then separate copper and aluminum fine particles and powder.

8. Separation of aluminum specific gravity: The metal particles separated above are copper-aluminum mixed particle powder. The difference in density of copper (density 8.9g/cm3) and aluminum (density 2.7g/cm3) is used to separate copper and aluminum by specific gravity. Specific gravity separation.

The waste lithium battery recycling and processing equipment realizes the waste lithium battery without waste gas crushing and recycling, and solves the problem of harmful gas leakage caused by the decomposition of lithium hexafluorophosphate in the existing lithium battery recycling technology. The cleaning of the solvent is more conducive to the crushing and pure separation of the subsequent pole pieces; the problem of sorting the stainless steel shell of the battery in the prior art is solved, and the stainless steel shell is separated by specific gravity sorting; the copper and aluminum particles are separated by air separation; The lithium battery recycling process and treatment system have low pollution, high efficiency, reasonable treatment process, little environmental pollution during the treatment process, and high recovery rate.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231