The radiator copper-aluminum separation system relates to the technical field of radiator copper-aluminum separation. The system includes a crusher, a crushing unit, and a vibration separation device in sequence according to the process steps. The crushing unit and the vibration separation device are respectively connected to a dust removal device through an air duct. The crusher is connected to the pulverizing unit through a conveyor belt, and the pulverizing unit is connected to the vibrating separation device through a magnetic separation conveyor belt.

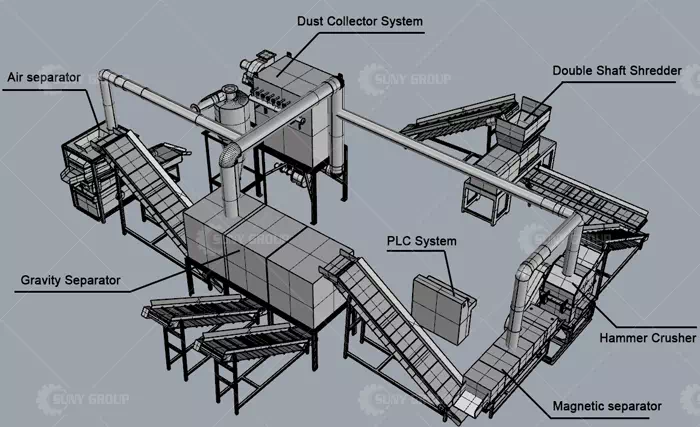

Radiator and aluminum separate machine layout

The copper-aluminum separation system provided by the present invention adopts a purely physical method to separate copper and aluminum, does not use any chemical reagents and separation liquid in the separation process, basically realizes zero discharge, does not cause any pollution to the environment, and has simple production process steps, which can realize Streamlined operation, high production efficiency, not only clean, environmentally friendly, but also energy-saving and efficient, complete separation of copper and aluminum, high purity.

Environmentally friendly and energy-saving radiator copper-aluminum separation system, the steps include a crusher, a crushing unit and a vibration separation device in sequence. The crushing unit and the vibration separation device are respectively connected to a dust removal device through the air duct, and the crusher and the crushing unit are connected by a conveyor belt. The crushing unit and the vibration separation device are connected by a magnetic separation conveyor belt; the dust removal device is composed of a fan and a bag filter, and the fan and the bag filter are connected through an air duct. The dust generated during the crushing and vibration separation process is blown by the fan The dust is sucked away, and sent into the bag filter 42 by the fan to filter and collect the dust; a magnetic separation impurity removal device is installed above the conveyor belt surface of the magnetic separation conveyor belt, and the crushed material processed by the crusher and the crushing unit of the radiator plate is It is transported to the vibration separation device through the magnetic separation conveyor belt. During the transportation process, the magnetic separation and impurity removal device can magnetically separate the iron material in the crushed material.

The radiator plate is crushed into crushed materials in the crusher, and the crushed materials are conveyed to the crushing unit through the conveyor belt to be processed into crushed materials, and the crushed materials are conveyed to the vibration separation device through the magnetic separation conveyor belt, and are passed through the magnetic separation conveyor belt during the conveying process. The impurity removal device separates the iron material in the crushed material by magnetic separation, and the crushed material after magnetic separation is completely separated from copper and aluminum in the vibration separation device.

The radiator contains copper and aluminum, which has high recyclable value. SUNY GROUP environmental protection copper-aluminum separation equipment radiator copper-aluminum separation technology is mature, and the copper and aluminum in the radiator are separated very well.

Thank you for your interest in suny group. If you want to learn more about our E-waste recycling plant, copper wire recycling machine and other machines, Contact us now to find out what we can do for you next project!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231